Inside Amazon Fulfillment Centers: What They Are and How They Operate

Ever wonder what actually happens after you click “Buy Now” on Amazon? Somewhere between that moment and the package landing at your door, there’s a system – fast, massive, and surprisingly intricate – that makes it all work. That’s where Amazon fulfillment centers come in.

These aren’t just warehouses. They’re high-speed hubs built to store, sort, pick, pack, and ship millions of products every single day. In this guide, we’ll break down what a fulfillment center really is, how it fits into the FBA process, and why understanding it matters if you’re selling on Amazon (or thinking about it). Let’s peel back the curtain.

A Fulfillment Center Isn’t Just a Warehouse

At first glance, it’s easy to confuse a fulfillment center with a regular warehouse. Both store stuff, right? But there’s a critical difference: a warehouse just holds inventory. A fulfillment center handles everything that happens after someone places an order.

Inside an Amazon fulfillment center, products don’t just sit around. They’re constantly moving through a well-orchestrated system that includes sorting, picking, packing, labeling, and shipping. Some are even returned, inspected, and restocked if they’re still in good condition.

In short, it’s where the real work happens after you click “Add to Cart.”

What Happens Inside an Amazon Fulfillment Center?

There’s a lot going on under one roof. These buildings often span over a million square feet, and some operate 24/7. Here’s a breakdown of what actually happens once a seller sends their inventory to Amazon.

1. Receiving and Storage

It starts with inbound shipments. Sellers using Fulfillment by Amazon (FBA) send their products to designated fulfillment centers. Once a shipment arrives, Amazon’s team scans each box, verifies contents, and sends items into storage. But don’t expect neatly organized rows by product type or brand.

Amazon doesn’t store items by category or shelf label. Instead, products are placed randomly, which sounds chaotic, but actually speeds up the picking process. This method, guided by complex algorithms, makes sure pickers are always moving efficiently through space.

2. Real-Time Inventory Management

Amazon tracks every item across its vast network with precision. Their systems know exactly where your product is, whether it’s on a high shelf in Phoenix or being picked for packing in a facility outside of Chicago.

This real-time tracking helps:

- Prevent stockouts.

- Improve restock forecasting.

- Keep customers updated on item availability.

3. The Pick, Pack, Ship Workflow

Once an order is placed, the center kicks into motion. Amazon’s software determines which fulfillment center is closest to the buyer and has the product in stock. From there:

- Pickers (assisted by handheld devices or robots) locate the item and move it to the packing area.

- Packers box up the order based on size, fragility, and shipping requirements.

- Shipping staff label it, scan it, and send it off through Amazon’s own delivery network or a third-party carrier.

All of this usually happens in just a few hours.

4. Returns and Quality Control

When a customer returns an item, it’s routed back to the same or nearest fulfillment center. There, Amazon inspects the product. If it’s still in like-new condition, it might be restocked and sold again. If not, it could be discarded or sent back to the seller.

There are also multiple checkpoints throughout the fulfillment process to make sure items aren’t damaged or mislabeled. Inventory Control and Quality Assurance teams constantly evaluate stock for errors, hazards, or missing barcodes.

How FBA Sellers Use Fulfillment Centers

For sellers using Fulfillment by Amazon (FBA), these centers are the backbone of their business. Amazon handles almost everything post-sale: storing inventory, fulfilling orders, dealing with customers, and managing returns.

Here’s what sellers are responsible for:

- Listing products on Amazon.

- Preparing and labeling items for shipment (or using a prep center to do this).

- Creating a shipping plan through Amazon Seller Central.

- Sending their products to the assigned fulfillment centers.

Once the items are checked in, Amazon takes care of the rest.

How Amazon Decides Where Your Inventory Goes

If you’ve ever shipped inventory to Amazon and wondered how they decide which fulfillment center it ends up in, it’s not random, and it’s definitely not based on what’s closest to you. The system behind it runs on data. Amazon uses a mix of forecasting, geography, shopping behavior, and shipping cost models to make those decisions.

Let’s say you’re selling surfboards. Amazon’s system knows that demand for those is higher near the coast, so your stock is more likely to land in California or Florida rather than somewhere like Kansas. It’s all about putting products where they’re most likely to move quickly, and where they can be delivered fast and affordably.

This approach helps Amazon maintain short delivery windows and keeps shipping costs lean. For sellers, though, it also means you don’t get to choose where your items are stored. Unless you’re using a third-party logistics provider to handle prep and positioning before it hits Amazon’s network, you’re trusting the algorithm to send things where they make the most logistical sense. And most of the time, it’s pretty good at that.

A Quick Look at the Costs

Using Amazon’s fulfillment centers isn’t free. Sellers using FBA pay several types of fees, including:

- Storage fees: Charged monthly per cubic foot. Rates increase during Q4 (holiday season).

- Fulfillment fees: Covers picking, packing, shipping, and customer service. Based on size and weight.

- Returns processing: If your product is returned, Amazon charges for the handling and inspection.

- Long-term storage or removal: If your products sit too long, you’ll either pay more to keep them there or pay to remove them.

Example: If you’re selling lightweight fitness bands (0.1 cubic foot, $2.40/cu ft during peak season), storing 1,000 units would cost around $240/month. Add in a $3.22 fulfillment fee per order, and that’s $3,460 in total for selling 1,000 units in October.

Why Sellers Choose Fulfillment by Amazon

Using Amazon’s fulfillment centers has both advantages and drawbacks. Here’s a quick breakdown to help you weigh the pros and cons.

Pros:

- Prime eligibility (which means more exposure and better conversion rates).

- Amazon handles shipping, customer service, and returns.

- Access to Amazon’s global logistics network.

- Scalability for fast-growing businesses.

Cons:

- Fees can stack up, especially for low-margin or slow-moving products.

- Less control over how items are packed or where they’re stored.

- Limited visibility into fulfillment decisions.

The Seller Experience: FBA vs. FBM

Amazon offers two main fulfillment options:

- Fulfilled by Amazon (FBA): You send inventory to Amazon, they handle the rest.

- Fulfilled by Merchant (FBM): You store and ship orders yourself.

FBA is ideal for:

- High-volume sellers.

- Businesses that want to scale quickly.

- Brands that prioritize Prime visibility.

FBM may be better for:

- Sellers with fragile or bulky products.

- Products with low turnover.

- Brands with their own fulfillment systems.

Behind the Scenes: What You Don’t See on the Order Page

There’s something impressive about watching a logistics engine run this smoothly, especially when millions of orders are being processed every day. The scale is hard to grasp unless you visit one of these facilities in person, which, by the way, you can actually do. Amazon offers virtual tours of some fulfillment centers.

And the tech keeps evolving. Expect to see even more AI-powered inventory forecasting, smart bidding systems, and predictive analytics rolled into Amazon’s future operations.

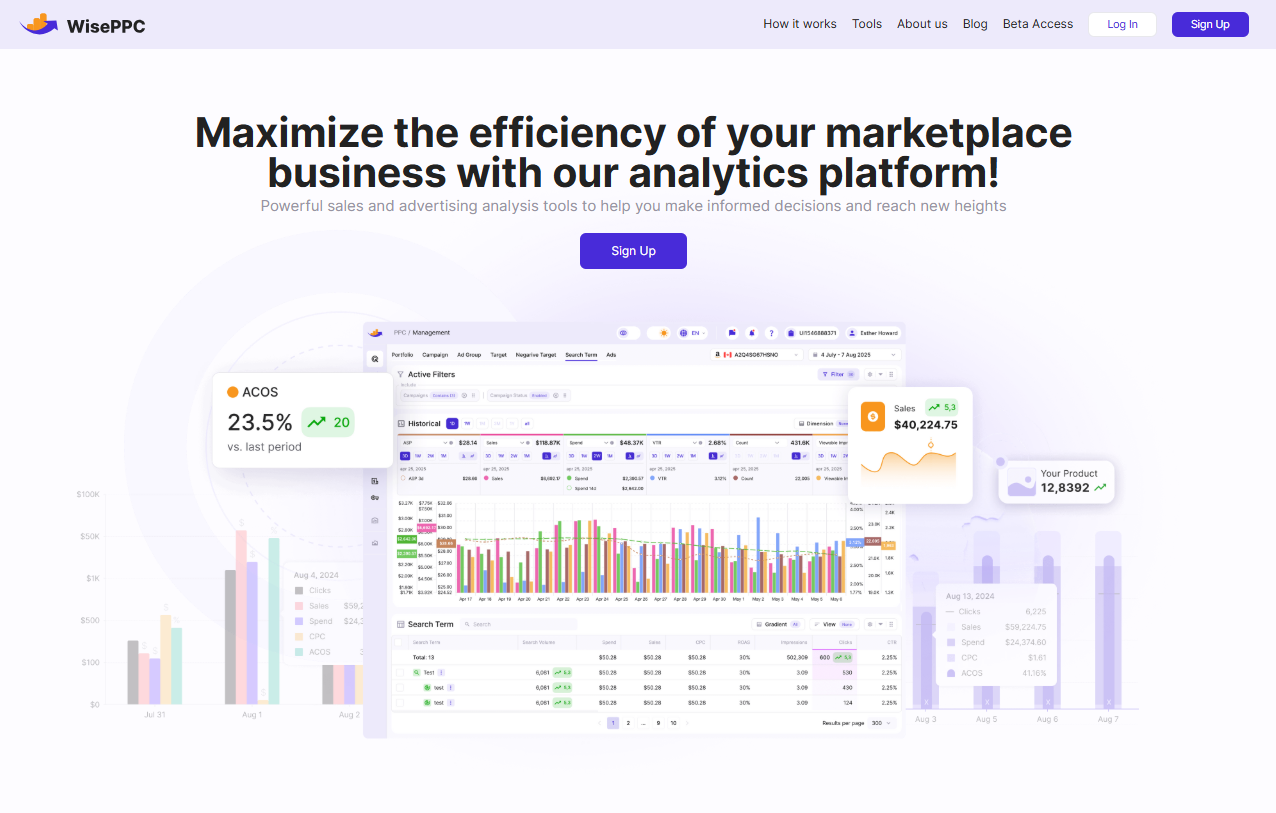

How WisePPC Helps Sellers Make the Most of Fulfillment and Performance Data

At WisePPC, we know that sending inventory to an Amazon fulfillment center is just one part of the bigger equation. What happens next – how your ads perform, how quickly products move, and what’s eating into your margins – can be the difference between scaling smoothly and burning budget. That’s exactly where we come in.

Our platform gives sellers the kind of visibility and control they wish they had inside Amazon’s own system. We don’t just show you sales numbers or ad clicks. We let you see the full picture: which campaigns are moving inventory, which keywords are draining spend, and how ad performance actually ties back to product velocity in fulfillment. With granular filtering, automated bid adjustments, and long-term historical tracking, we help you react faster and plan smarter, without drowning in spreadsheets or guesswork.

Whether you’re managing 10 SKUs or 10,000, fulfillment doesn’t happen in a vacuum. Sales data, ad strategy, and marketplace logistics are all connected. We built WisePPC to make those connections clear, so you can scale without the chaos. If you’re serious about using Amazon fulfillment as a foundation for growth, we’re here to help you optimize what comes next.

Conclusion

Amazon fulfillment centers are more than just warehouses with shelves. They’re fast-moving, highly automated command centers designed to get products from shelf to doorstep in record time.

If you’re selling on Amazon, understanding how these fulfillment centers operate isn’t just interesting – it’s strategic. Knowing how inventory flows, how fees add up, and how automation works behind the scenes can help you make smarter choices about how and where to scale.

Because at the end of the day, Amazon’s system might feel like magic to a shopper. But to a seller? It’s a machine you need to understand if you want to grow.

FAQ

1. How is an Amazon fulfillment center different from a regular warehouse?

It’s not just about storage. A regular warehouse holds inventory, but a fulfillment center handles the entire process of getting products to customers – receiving, picking, packing, shipping, and even returns. Think of it as a high-speed operations hub where products don’t sit still for long.

2. Do sellers get to choose which fulfillment center their inventory goes to?

Not really. Once you create a shipping plan in Seller Central, Amazon decides where to send your inventory based on where they expect demand to be. They’re trying to keep things fast and efficient, so unless you’re working with a third-party prep service, you don’t have much control over where your boxes land.

3. Is Fulfillment by Amazon (FBA) worth it for small sellers?

It depends on your product margins and how hands-off you want to be. FBA is great for saving time and tapping into Prime customers, but the fees can add up quickly, especially if you’re not moving inventory fast. For some sellers, it’s a game-changer. For others, Fulfilled by Merchant might make more sense.

4. What happens if a customer returns an item through FBA?

Returns go straight back to the fulfillment center. Amazon checks the product and decides if it can be resold, needs to be disposed of, or should be sent back to you. You don’t have to lift a finger, but you might see some fees depending on what they do with the item.

5. Can I send inventory to just one Amazon fulfillment center to save on shipping?

Amazon typically splits shipments across multiple fulfillment centers based on where they need stock. That’s how they keep delivery times short. You can use programs like Inventory Placement Service to send everything to one location, but there’s usually an added fee.

6. How long does Amazon store inventory before charging extra?

Amazon charges standard monthly storage fees, but if your products sit for more than 180 days, you could get hit with long-term storage fees. It’s their way of encouraging sellers to keep inventory moving, not collecting dust. Regular clean-ups or removals can help you avoid surprise charges.

Join the WisePPC Beta and Get Exclusive Access Benefits

WisePPC is now in beta — and we’re inviting a limited number of early users to join. As a beta tester, you'll get free access, lifetime perks, and a chance to help shape the product — from an Amazon Ads Verified Partner you can trust.

No credit card required

No credit card required

Free in beta and free extra month free after release

Free in beta and free extra month free after release

25% off for life — limited beta offer

25% off for life — limited beta offer

Access metrics Amazon Ads won’t show you

Access metrics Amazon Ads won’t show you

Be part of shaping the product with your feedback

Be part of shaping the product with your feedback