Essential Steps to Build an Effective Amazon Inventory Management Strategy

Effective inventory management is critical to maintaining a competitive edge on Amazon. A well-crafted strategy helps ensure you meet customer demand, avoid overstocking or stockouts, and improve your overall sales performance. In this article, we explore building effective strategy that can streamline your Amazon inventory management, maximize efficiency, and minimize costs.

What Is Amazon Inventory Management?

Amazon inventory management refers to the process of overseeing and controlling the flow of products within the Amazon ecosystem. From sourcing products to managing stock levels, and even forecasting demand, Amazon sellers need to ensure their products are consistently available for customers without overstocking.

A well-managed inventory helps sellers maintain their position in Amazon’s rankings, ensure fast delivery times, and ultimately drive more sales. Effective inventory management doesn’t just involve keeping products in stock but also predicting future sales trends, managing stock levels based on demand, and making data-driven decisions.

Amazon Inventory Management Strategy Definition

An Amazon inventory management strategy is a comprehensive approach that sellers use to track, manage, and optimize their product stock on Amazon. It involves everything from forecasting demand and ensuring the right amount of stock is available to customers, to minimizing storage costs and avoiding issues like stockouts or excess inventory.

The goal is to keep products in stock without overstocking, manage supply chain operations efficiently, and utilize Amazon’s tools and services, such as Fulfillment by Amazon (FBA), to streamline processes. A well-executed strategy can help sellers improve sales, reduce operational costs, and enhance customer satisfaction, ultimately contributing to long-term business success on the platform.

Components of an Amazon Inventory Management Strategy

A well-rounded Amazon inventory management strategy is made up of several essential components that work together to ensure smooth operations, maintain proper stock levels, and minimize costs. These components help sellers effectively manage the flow of inventory, anticipate demand, and avoid issues like stockouts, overstocking, or excessive storage fees. Here are the key components that make up a successful Amazon inventory management strategy:

Demand Forecasting

One of the most important elements of an Amazon inventory management strategy is demand forecasting. This involves analyzing historical sales data to predict future demand for your products. The goal is to understand when your products will sell and at what rate so that you can order enough stock in advance, avoiding stockouts or excess inventory.

- Tools: Amazon’s Selling Coach and third-party tools can help forecast demand by analyzing your sales trends and inventory levels.

- Seasonal trends: be aware of peak seasons, such as holidays or Black Friday, which often require adjusting stock levels.

Inventory Replenishment

Inventory replenishment is the process of ordering new stock to replace what’s sold. It’s important to have a system that helps you know when to reorder and how much stock you need.

- Replenishment triggers: using tools like Amazon’s Inventory Performance Index (IPI), you can set automatic alerts for when stock levels drop below a certain threshold.

- Lead times: factor in supplier lead times and shipping delays to ensure your inventory arrives on time.

Product Listing Optimization

Your product listings are your storefront on Amazon. Optimizing them not only helps customers find your products but also plays a role in managing your inventory.

- Accurate descriptions: Make sure your product descriptions reflect current stock and are optimized for search engines.

- High-quality images: Clear, professional images can improve sales, helping you manage inventory more effectively by boosting product turnover.

Storage and Fulfillment

Amazon offers different fulfillment methods like Fulfilled by Amazon (FBA) and Fulfilled by Merchant (FBM). FBA is the most common, as it allows you to leverage Amazon’s vast fulfillment network.

- Storage fees: FBA charges storage fees based on the size and duration of your inventory in Amazon’s warehouses. It’s essential to manage the amount of stock you send to Amazon to avoid high storage costs.

- Space management: keep track of how much space your inventory occupies in the warehouse. Overstocking can lead to additional fees and reduced margins.

Stock Monitoring and Reporting

Keeping track of your stock in real-time is essential for managing your Amazon inventory effectively. Regular stock audits and performance reports give you an insight into what products are selling and which ones are not.

- Inventory management software: Different tools can help you automate the process and track stock levels in real-time.

- Regular audits: periodic audits help you reconcile actual stock levels with the numbers in your system, ensuring you don’t face discrepancies.

Steps to Creating a Profitable Amazon Inventory Management Strategy

Building an effective Amazon inventory management strategy requires consistent effort, analysis, and fine-tuning over time. It’s not something you can perfect overnight, but taking the right steps can lead to a more profitable and efficient operation. Here are the essential steps to developing a successful strategy for your Amazon business:

Step 1. Understand Your Sales and Stock Levels

The first step in building a profitable inventory management strategy is understanding your sales patterns and current stock levels. By analyzing your data, you can make informed decisions about how to manage your inventory efficiently.

Sales Data

Review your historical sales data to identify trends, such as which products sell the most and during which time periods. This allows you to understand demand fluctuations and plan ahead.

Inventory Turnover Rate

Track how quickly your stock is turning over. Products that sell quickly should be replenished more frequently, while slow-moving items may need different strategies, such as promotions or discounts to clear them out.

By understanding your sales patterns and turnover rate, you can better anticipate the demand for each product and adjust your stock levels accordingly.

Step 2. Use Automated Tools for Demand Forecasting

Accurately predicting demand is essential for maintaining stock levels without overstocking. While manual forecasting can be challenging, leveraging the right tools can streamline this process.

Amazon Selling Coach

Amazon provides this tool within Seller Central to offer personalized restocking recommendations based on your sales history, helping you plan ahead.

Third-Party Tools

Consider using third-party inventory management tools which provide advanced forecasting features and allow for more precise demand planning.

Using automated tools simplifies demand forecasting, reduces the risk of stockouts and overstocking, and ultimately improves your inventory management strategy.

Step 3. Set Reorder Points and Safety Stock Levels

Knowing when to reorder products is key to staying on top of your inventory. Setting the correct reorder points ensures you won’t run out of stock, and having safety stock is essential during high-demand periods.

Reorder Points

This is the inventory level at which you need to place a new order. Using your sales data and forecasting tools, calculate when to reorder based on your sales velocity.

Safety Stock

Keep extra inventory in reserve, particularly during peak seasons or when you have unreliable suppliers. This buffer stock helps to prevent stockouts due to unexpected demand spikes or supply chain delays.

Lead Time Considerations

Take into account supplier lead times and shipping delays. International shipments, in particular, may have longer lead times, so planning ahead is critical to maintaining a steady inventory flow.

Setting reorder points and safety stock levels helps ensure you are always prepared to meet demand, avoiding stockouts while reducing excess inventory.

Step 4. Optimize Your Product Listings and Promotions

Your product listings play a critical role in inventory management. A well-optimized listing not only improves visibility but also drives sales, helping to move your inventory faster.

SEO for Listings

Ensure your listings are optimized for search engines by including relevant keywords in your title, bullet points, and product descriptions. This will help customers find your products more easily.

Promotions and Discounts

Running promotions and offering discounts can help move slow-moving inventory. However, it’s important to be strategic. Overly aggressive promotions might lead to stockouts, so plan promotions carefully based on your inventory levels.

Optimizing listings and strategically using promotions helps boost sales and inventory turnover, contributing to a healthier and more profitable inventory system.

Step 5. Implement Stock Monitoring Systems

Real-time tracking and automated alerts are vital for keeping your inventory under control. Monitoring systems help you stay on top of stock levels, prevent discrepancies, and quickly respond to issues.

Real-Time Alerts

Set up alerts in Amazon Seller Central or use inventory management software to notify you when stock levels are running low or if there are discrepancies in your inventory.

Reconciliation

Regularly reconcile your inventory with both Amazon’s records and your suppliers’ data. This ensures you address discrepancies like lost or damaged stock in a timely manner.

Conclusion: Stock monitoring systems are essential for staying proactive, ensuring that your inventory is accurately tracked and allowing you to react quickly to prevent stock issues.

Step 6. Review and Adjust Regularly

Inventory management is an ongoing process that requires constant evaluation and adjustment. Regular reviews help ensure your strategy stays aligned with market changes and customer demand.

Monthly Reports

Generate regular inventory reports to assess how well your strategy is performing. Look for patterns or areas where adjustments may be needed.

Adapt to Trends

Stay flexible and be ready to adjust your strategy based on market trends, customer demand, and any updates to Amazon’s policies. Being adaptable allows you to stay ahead of changes and keep your inventory strategy optimized.

Regularly reviewing and adjusting your strategy is essential for long-term success. By staying proactive, you can make data-driven decisions and ensure your inventory strategy is always in sync with market needs.

Best Practices for Amazon Inventory Management Strategy

By following best practices, you can optimize your processes, improve your Amazon rankings, and ensure a smooth and profitable operation. Below are some best practices that will guide you in creating and maintaining a reliable and efficient inventory management strategy on Amazon.

Maintain Balanced Stock Levels

Finding the balance between too much and too little inventory is crucial for Amazon sellers. Overstocking increases your storage fees and ties up your capital, while understocking can lead to stockouts and missed sales opportunities.

- Track your sales trends: monitor sales velocity to adjust stock levels accordingly.

- Use historical data: analyze past sales to predict future demand and order accordingly.

Optimize for Amazon’s Performance Metrics

Amazon uses metrics like the Inventory Performance Index (IPI) to assess how well sellers manage their inventory. A low IPI score can result in increased storage fees and reduced storage limits.

- Sell-through rate: A high sell-through rate indicates that your inventory is moving quickly, positively impacting your IPI score.

- Stranded inventory: Avoid stranded inventory by ensuring that all product listings are active and optimized.

Leverage FBA for Easier Fulfillment

If you’re not already using Fulfilled by Amazon (FBA), consider making the switch. FBA simplifies inventory management by outsourcing storage, picking, packing, and shipping to Amazon. It also allows you to take advantage of Amazon’s Prime eligibility.

- Reduced shipping time: FBA enables faster shipping, which can lead to higher customer satisfaction and better reviews.

- Prime eligibility: Products fulfilled by Amazon are eligible for Amazon Prime, which can help increase visibility and sales.

Consider Dropshipping for Low-Risk Stocking

If you’re looking to avoid holding large amounts of inventory, dropshipping can be a viable option. With dropshipping, you only order products when customers place an order, meaning there’s less risk involved.

- No upfront costs: you don’t need to buy inventory upfront, which reduces financial risk.

- Supplier compliance: ensure that your dropshipping suppliers meet Amazon’s shipping and reporting standards to avoid issues with your account.

Plan for Seasonal and Promotional Demands

Planning for seasonal sales fluctuations is key to managing inventory. Whether it’s Black Friday, Cyber Monday, or the holiday season, you need to anticipate higher demand and adjust stock levels accordingly.

- Increase stock for peak seasons: order extra stock ahead of time for busy periods.

- Adjust pricing during promotions: during promotions, increase prices once the sale ends to slow down demand if needed.

By applying these best practices to your Amazon inventory management strategy, you’ll be able to balance stock levels, optimize for Amazon’s performance metrics, streamline fulfillment, minimize financial risk, and prepare for fluctuating demand.

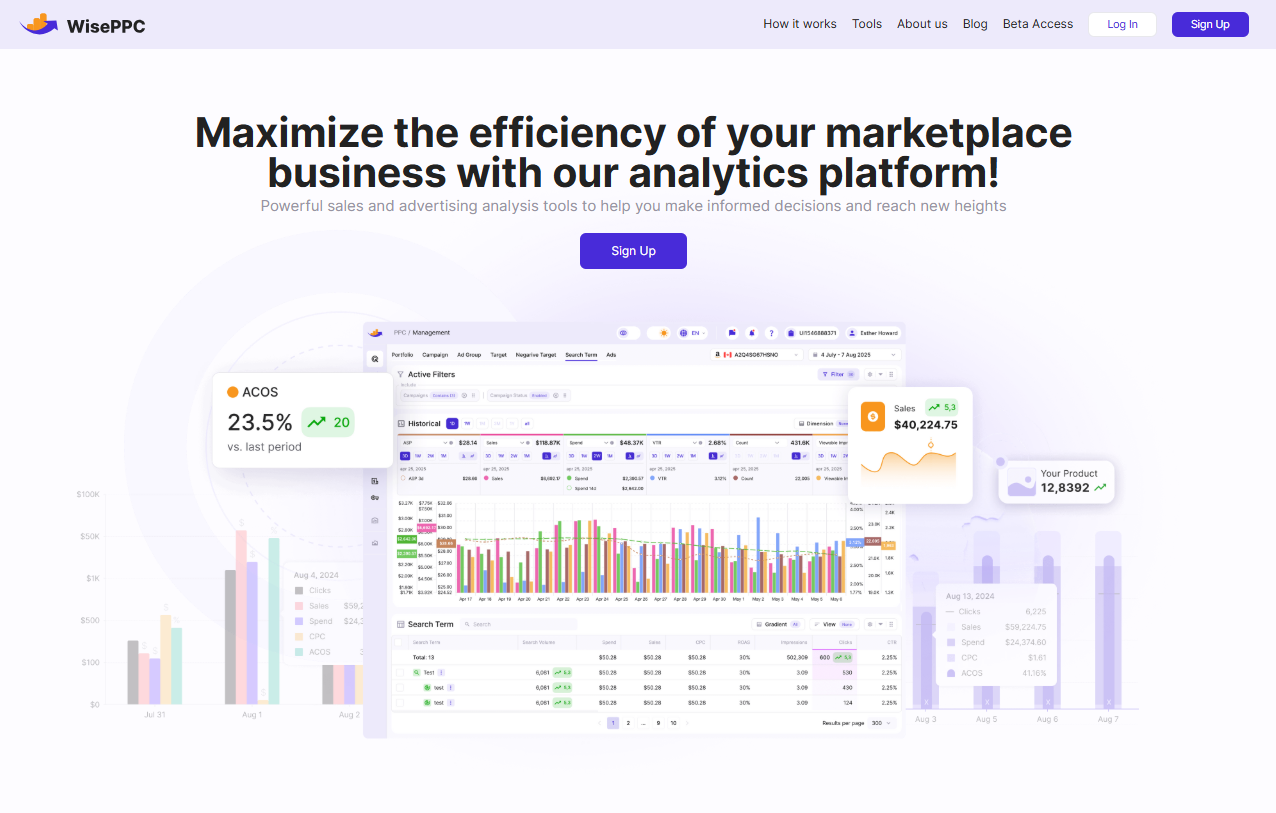

WisePPC: Enhancing Your Amazon Inventory Management Strategy with Advanced Analytics

At WisePPC, we understand the importance of a well-organized inventory management strategy for Amazon sellers. Our platform offers a suite of tools designed to help you optimize not only your advertising efforts but also your inventory management. By providing deep insights into sales performance, ad effectiveness, and stock movement, WisePPC empowers you to make data-driven decisions that improve stock levels, reduce costs, and ultimately drive better profitability. As an Amazon Ads Verified Partner, we ensure that all our tools follow Amazon’s best practices, helping you manage your inventory and ads seamlessly in one place.

WisePPC’s advanced analytics platform allows you to track inventory performance in real-time, predict future demand, and adjust your stock levels accordingly. With features like bulk actions, historical data analysis, and intelligent ad optimization, you can streamline your inventory management and advertising strategies, ensuring that you never run out of stock or overstock. Our tools provide a comprehensive view of your sales data, which can directly inform your replenishment decisions, help you maintain healthy stock levels, and avoid costly storage fees.

Services Provided by WisePPC

Bulk Actions

Apply changes to multiple campaigns, ad groups, or targets at once, saving time on inventory and ad management tasks.

Advanced Filtering

Use powerful filters to segment and analyze performance based on different inventory and sales metrics.

Historical Metrics Charts

Visualize past sales trends and inventory performance over different time frames, helping you predict future demand and manage stock accordingly.

Real-Time Performance Monitoring

Track your sales and inventory levels in real-time, ensuring that your products are always available for customers while minimizing storage costs.

Placement Performance Analysis

Understand the effectiveness of your ad placements, which can help you adjust your advertising strategy to move slow-moving inventory or maximize high-demand products.

Automated Optimization

Let WisePPC automate campaign adjustments, highlighting underperforming products and suggesting adjustments for better ad spend efficiency, which directly impacts your inventory turnover rate.

By integrating WisePPC into your Amazon inventory management strategy, you can make more informed decisions regarding stock levels, promotions, and replenishment cycles, leading to better sales outcomes and a more efficient inventory system.

Conclusion

In today’s competitive Amazon marketplace, effective inventory management is key to maintaining a healthy business. A well-designed inventory management strategy ensures that products are available for customers without tying up excessive capital in unsold stock.

By forecasting demand, setting reorder points, optimizing product listings, and leveraging Amazon’s tools, sellers can strike the right balance between stock levels and operational costs. Regular monitoring and adjustments to the strategy based on real-time data help sellers stay ahead of trends, manage their supply chain efficiently, and ultimately boost profitability.

The goal is not just to manage stock, but to create a strategy that supports growth, reduces wasted resources, and improves the customer experience. A strategic approach to inventory management, complemented by automation and analytics tools, can make a significant difference in the success of an Amazon business.

FAQ

1. Why is inventory management crucial for Amazon sellers?

Inventory management is critical for Amazon sellers because it helps maintain the right stock levels to meet customer demand while avoiding issues like stockouts and overstocking. Effective inventory management ensures that you don’t miss sales opportunities due to insufficient stock, and it helps control costs associated with storing and handling excess inventory.

2. How do I forecast demand for my Amazon products?

Demand forecasting on Amazon involves analyzing historical sales data, reviewing trends, and understanding seasonal fluctuations. Sellers can use third-party tools for more advanced forecasting, considering factors such as market trends, promotions, and customer behavior, which helps predict future demand and adjust inventory levels accordingly.

3. What are the consequences of poor inventory management on Amazon?

Poor inventory management can lead to stockouts, resulting in missed sales and poor customer reviews. On the other hand, overstocking can incur high storage fees and tie up cash flow. Both can negatively impact your seller performance metrics, such as the Inventory Performance Index (IPI), which Amazon uses to assess how efficiently you manage inventory.

4. How can I avoid overstocking and understocking on Amazon?

To avoid overstocking and understocking, it’s essential to use data-driven tools for demand forecasting, set appropriate reorder points, and maintain a safety stock during peak seasons. Regularly monitor your sales velocity, inventory levels, and market trends to ensure you’re ordering the right amount of stock at the right time.

5. How can I optimize my Amazon product listings to support inventory management?

Optimizing your product listings is essential for moving inventory efficiently. Accurate and compelling product descriptions, high-quality images, and relevant keywords ensure that your products are easily discoverable by potential customers. Well-optimized listings also lead to higher conversion rates, which helps increase sales velocity and manage stock turnover.

Join the WisePPC Beta and Get Exclusive Access Benefits

WisePPC is now in beta — and we’re inviting a limited number of early users to join. As a beta tester, you'll get free access, lifetime perks, and a chance to help shape the product — from an Amazon Ads Verified Partner you can trust.

No credit card required

No credit card required

Free in beta and free extra month free after release

Free in beta and free extra month free after release

25% off for life — limited beta offer

25% off for life — limited beta offer

Access metrics Amazon Ads won’t show you

Access metrics Amazon Ads won’t show you

Be part of shaping the product with your feedback

Be part of shaping the product with your feedback