Amazon Partnered Carrier Program: How It Works and When to Use It

Shipping inventory to Amazon is one of those tasks that looks simple until it isn’t. Rates fluctuate, rules change, and small mistakes can quietly eat into margins. That’s where the Amazon Partnered Carrier Program comes in. It’s Amazon’s way of simplifying inbound shipping for sellers, offering negotiated rates and a more controlled process inside Seller Central.

This guide breaks down what the program actually is, how it works in practice, and why many FBA sellers rely on it as they scale. No hype, no shortcuts. Just a clear look at whether this shipping option fits your operation and when it makes sense to use it.

What the Amazon Partnered Carrier Program Is

At its core, the Amazon Partnered Carrier Program is an inbound shipping service designed for sellers sending inventory to Amazon fulfillment centers. Instead of arranging shipping directly with UPS, FedEx, or freight brokers, sellers can book shipping through Amazon using carriers Amazon already works with.

Amazon negotiates the rates, integrates the shipment into Seller Central, and charges the shipping cost directly to the seller account. The seller still owns the inventory, but the logistics flow is guided by Amazon’s system.

This program is primarily built for Fulfillment by Amazon shipments, but it also supports other Amazon logistics workflows, including Amazon Warehousing and Distribution and Multi-Channel Fulfillment in certain cases.

The value of the program is not just lower pricing. It is the combination of pricing, integration, tracking, and compliance with Amazon’s inbound requirements.

Why Amazon Created This Program

Amazon fulfillment centers run on predictability. When inbound shipments arrive late, mislabeled, or incomplete, it creates operational issues that ripple through the system. Over time, Amazon learned that many of these issues started before the shipment even left the seller’s warehouse.

By partnering directly with carriers, Amazon gained more control over how inventory moves into its network. Sellers benefit from that control through simpler workflows and fewer compliance surprises.

The program is designed to standardize inbound shipping without forcing sellers into a single carrier or shipment type. It gives Amazon better visibility and gives sellers a cleaner process.

Shipping Options Inside the Program

The Amazon Partnered Carrier Program supports three main shipment types. Each serves a different scale and purpose.

1. Small Parcel Delivery (SPD)

Small Parcel Delivery is used when inventory is shipped in individual boxes rather than pallets. Each box is labeled separately and moves through standard parcel networks.

This option is commonly used for:

- Smaller replenishment shipments

- Lightweight or mixed SKUs

- Sellers shipping up to 200 boxes per shipment.

Carriers typically include UPS and other regional services depending on the marketplace location.

SPD is flexible and fast, but it becomes inefficient as shipment size grows. Labeling hundreds of boxes and managing parcel pickups adds labor and cost at scale.

2. Less Than Truckload (LTL)

LTL shipping is designed for palletized shipments that are too large for parcel delivery but do not require a full trailer.

Multiple sellers share space on the same truck, which keeps costs lower than full truckload shipping.

LTL is commonly used when:

- Shipments weigh between 150 and 15,000 pounds

- Inventory is palletized and shrink-wrapped

- Sellers want a balance between cost and speed

This option requires basic freight readiness, including pallets, forklifts or liftgate access, and accurate weight and dimension reporting.

3. Full Truckload (FTL)

Full Truckload shipping dedicates an entire trailer to a single shipment. There are fewer stops, less handling, and usually faster delivery.

FTL makes sense when:

- Shipments exceed 15,000 pounds or consist of more than 12 pallets

- Inventory fills most or all of a trailer

- Speed and reduced handling matter more than cost

While FTL is more expensive upfront, it can reduce damage risk and receiving delays for high-volume sellers.

How the Program Works Inside Seller Central

Using the Amazon Partnered Carrier Program starts during shipment creation. Sellers do not need to sign separate carrier agreements or create new accounts.

The general workflow looks like this:

First, the seller creates an inbound shipment in Seller Central using the Send to Amazon or FBA Shipments workflow.

Next, shipment details are entered, including ship-from address, box or pallet information, weights, and dimensions.

During the carrier selection step, the seller chooses Amazon Partnered Carrier instead of a non-partnered option.

Amazon then calculates shipping costs based on the provided information. These rates reflect Amazon’s negotiated pricing.

Once the seller accepts the charges, shipping labels are generated directly in Seller Central.

For SPD shipments, box labels are printed and applied. For LTL and FTL shipments, pallet and shipment labels are prepared.

Finally, the seller schedules a pickup with the selected carrier or prepares the shipment for delivery based on the carrier’s process.

Tracking information is automatically linked to the shipment inside Seller Central.

The Real Benefits Sellers Care About

The program is often described as convenient, but convenience alone is not enough to justify a logistics decision. The real benefits show up in day to day operations.

Lower Shipping Costs

Amazon’s negotiated rates are often significantly lower than what individual sellers can secure on their own, especially for small and mid-sized businesses.

Savings vary by shipment type and distance, but reductions of 30 to 50 percent compared to retail carrier pricing are common.

Over time, these savings compound, especially for sellers who replenish inventory frequently.

Integrated Tracking and Fewer Systems

Managing inbound shipments across multiple carrier dashboards creates blind spots. The Partnered Carrier Program keeps everything inside Seller Central.

Shipment status, tracking events, and delivery confirmations all live in one place. This reduces follow-ups, screenshots, and manual checks.

When something goes wrong, having the shipment tied directly to Amazon’s system often speeds up resolution.

Better Alignment With Amazon’s Rules

Amazon is strict about labeling, box content, and shipment accuracy. Partnered carriers are already familiar with Amazon’s fulfillment network.

That familiarity reduces the risk of:

- Missed delivery appointments

- Incorrect warehouse routing

- Label placement errors

Fewer mistakes mean fewer delays and fewer unexpected fees.

Easier Payments and Accounting

Shipping charges are billed directly to the seller’s Amazon account. There are no separate invoices to reconcile or carrier statements to audit.

This simplifies bookkeeping and gives sellers a clearer view of true landed costs.

Amazon Partnered Carrier Program vs Other Shipping Options

Choosing the right shipping setup is less about finding a perfect solution and more about understanding tradeoffs. The Amazon Partnered Carrier Program emphasizes simplicity and predictability, while alternative carriers offer more control and room for negotiation. The table below breaks down where each option tends to work best, based on real operational scenarios sellers run into.

| Scenario | Amazon Partnered Carrier Program | Alternative Shipping Options |

| Regular FBA replenishment | Ideal for sellers shipping inventory on a consistent schedule. Integrated workflow reduces admin work and keeps shipping predictable. | Often adds extra steps, separate tracking, and manual reconciliation. |

| Small to mid-sized sellers | Strong fit when sellers lack leverage to negotiate discounted carrier rates independently. | Discounts may be limited without high shipping volume or long-term contracts. |

| Focus on simplicity | Centralized shipping, labels, billing, and tracking inside Seller Central. Minimal setup and fewer moving parts. | More control, but requires managing carrier accounts, invoices, and logistics tools. |

| Scaling inventory volume | Predictable costs and streamlined processes support growth and inventory planning. | Can work, but complexity increases as shipment volume grows. |

| Sellers with negotiated freight contracts | Rates may be less competitive compared to existing enterprise-level agreements. | Often better pricing and tailored service levels for high-volume shippers. |

| Complex routing or logistics | Limited flexibility for non-standard routing or custom workflows. | Greater control over routing, consolidation, and special handling. |

| International shipping workflows | Works best when paired with Amazon Global Logistics in supported regions. | Preferred when using dedicated freight forwarders or custom customs processes. |

| Overall tradeoff | Prioritizes ease of use, integration, and predictability. | Prioritizes control, customization, and negotiation flexibility. |

When Careful Planning Beats Rushing Shipments

Rushing through shipment creation is one of the most common and expensive mistakes sellers make. The Amazon Partnered Carrier Program is built for efficiency, but it still depends on accurate inputs and thoughtful planning. Slowing down at the right moments often prevents delays, adjustments, and unnecessary costs later.

Why Accurate Measurements Matter

Amazon calculates shipping fees based on the data entered during shipment creation. If box dimensions or weights are incorrect, even by a small margin, sellers may face adjustment fees, delayed receiving, or compliance issues.

Accurate measurement is not optional. It is part of keeping shipments predictable and cost-effective. Taking time to weigh and measure inventory correctly helps avoid surprises and keeps inventory flowing smoothly into Amazon’s fulfillment centers.

Inventory Planning and Smarter Shipping

The Partnered Carrier Program works best when shipping decisions are connected to inventory planning instead of last-minute fixes. Sending frequent small shipments often costs more over time than fewer, well-planned deliveries.

Sellers who review sales velocity, seasonality, and ad performance can align shipment timing with actual demand. This approach reduces stockouts and limits rushed shipments that drive costs higher.

Using the Program as an International Seller

In regions where the program is available, international sellers can benefit as well, especially when the program is paired with Amazon Global Logistics. This setup allows inventory to move across borders while remaining within Amazon’s logistics ecosystem.

Keeping shipping, customs, and delivery under one framework reduces handoffs and simplifies coordination. Fewer external partners often mean fewer delays and clearer accountability.

Canceling and Adjusting Shipments Without Surprises

Even with careful planning, changes happen. Amazon allows shipment cancellations, but the timing matters.

Small Parcel Delivery shipments usually need to be canceled within 24 hours. For LTL and FTL shipments, the window is much shorter, often limited to one hour after accepting charges.

Canceling a shipment does not always remove fees automatically. Following the cancellation steps carefully helps avoid unexpected charges or pickups that no longer align with the plan.

Common Pitfalls to Avoid

Even with a streamlined system, sellers can still run into avoidable issues when using the Amazon Partnered Carrier Program. Most problems happen during shipment setup, not during transit.

Some of the most common mistakes include:

- Incorrect box counts: Entering the wrong number of boxes can trigger receiving delays or reconciliation issues once the shipment arrives at the fulfillment center.

- Mismatched weights and dimensions: Differences between declared and actual measurements often lead to adjustment fees or shipment reclassification after pickup.

- Missing or duplicated labels: Labels that are missing, damaged, or applied more than once can cause inventory to be misrouted or temporarily lost during receiving.

- Incomplete pickup instructions: Failing to note warehouse hours, liftgate requirements, or access restrictions can result in missed pickups or rescheduling delays.

Most of these issues are preventable. A final review of shipment details before accepting shipping charges helps catch errors early and keeps inbound shipments on schedule.

Is the Program Worth Using?

For most FBA sellers, the answer is yes.

The Amazon Partnered Carrier Program removes complexity from one of the least forgiving parts of selling on Amazon. It is not about chasing the lowest possible rate at any cost. It is about balancing savings, reliability, and operational clarity.

Sellers who understand how it works and use it intentionally tend to see smoother inbound logistics and fewer surprises.

How We Help Amazon Sellers Make Better Decisions With Data at WisePPC

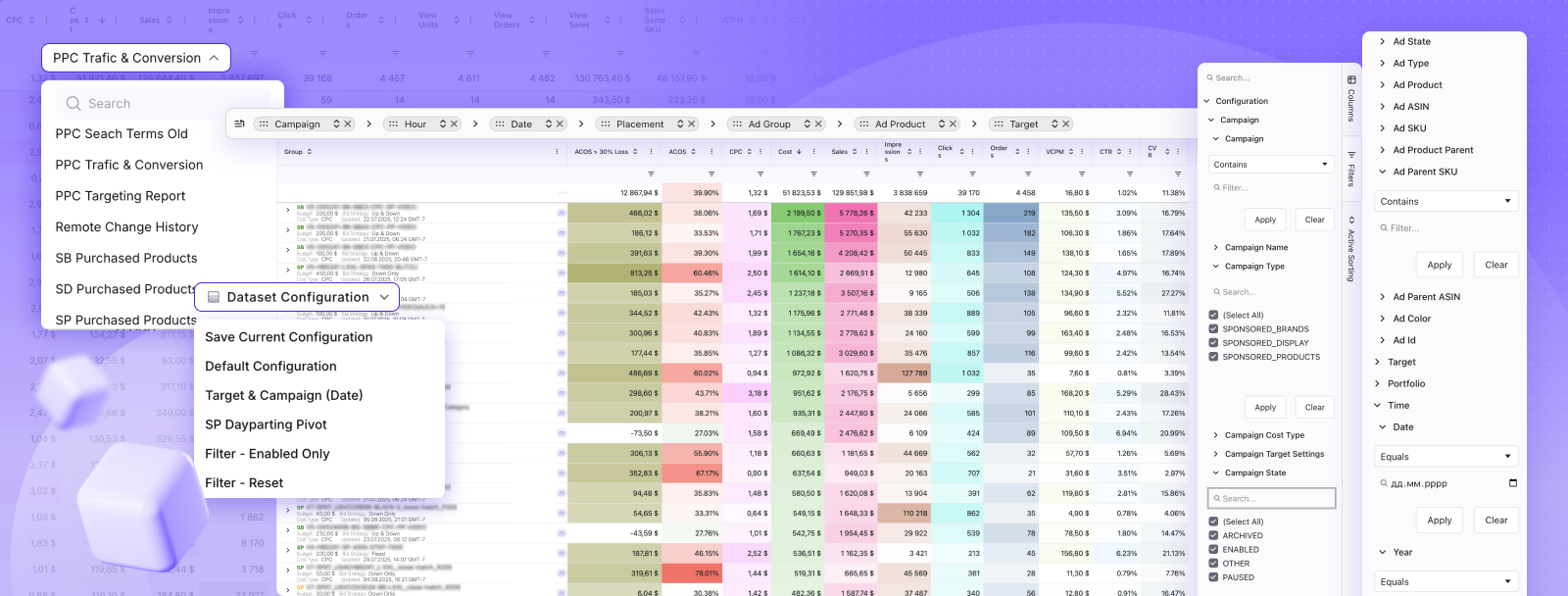

At WisePPC, we focus on one thing: giving marketplace sellers clear, reliable data they can actually use. Our platform brings together advertising performance, sales metrics, and long-term historical data so teams can see what’s driving results and where things start to break down.

We built WisePPC around deep analytics and control. Sellers can analyze performance across campaigns, keywords, placements, and products, apply bulk actions to thousands of entities at once, and spot issues quickly through advanced filtering and visual highlights. Instead of jumping between tools or working off partial data, everything lives in one system.

Because we store years of historical data, not just the last few months, sellers can compare performance over time, understand seasonality, and make more informed decisions as they scale. With official Amazon integrations and real-time insights, our goal is simple: replace guesswork with clarity, so every operational decision is backed by data, not assumptions.

Final Thoughts

The Amazon Partnered Carrier Program is not a growth hack. It is infrastructure. When used correctly, it quietly supports scaling by making inventory movement more predictable and manageable.

Shipping will never be exciting, but it does not have to be painful. For many sellers, this program turns a recurring headache into a routine task that just works.

Understanding when and how to use it is part of building a resilient Amazon business.

Frequently Asked Questions

What is the Amazon Partnered Carrier Program in simple terms?

The Amazon Partnered Carrier Program is a built-in shipping option that lets sellers send inventory to Amazon fulfillment centers using carriers Amazon already works with. Shipping is booked inside Seller Central, rates are pre-negotiated by Amazon, and charges are applied directly to the seller account.

Is the Amazon Partnered Carrier Program required for FBA sellers?

No. The program is optional. Sellers can still use their own carriers when shipping inventory to Amazon. The partnered option exists to simplify the process and offer competitive rates, not to replace every shipping setup.

Does using a partnered carrier guarantee lower shipping costs?

Not always, but often. For small to mid-sized sellers, Amazon’s negotiated rates are usually lower than standard carrier pricing. Sellers with strong freight contracts or very high shipping volume may sometimes get better rates outside the program.

Can I choose between small parcel, LTL, and FTL shipping?

Yes. The program supports Small Parcel Delivery, Less Than Truckload, and Full Truckload shipments. The best option depends on shipment size, weight, and how frequently inventory is replenished.

How are shipping charges billed?

Shipping costs are charged directly to your Amazon seller account after you accept the estimated fees during shipment creation. There are no separate carrier invoices to manage.

What happens if my box dimensions or weights are wrong?

If actual measurements do not match what was entered during shipment creation, Amazon may apply adjustment fees or delay receiving. Accurate weights and dimensions are essential for avoiding unexpected charges.

Join the WisePPC Beta and Get Exclusive Access Benefits

WisePPC is now in beta — and we’re inviting a limited number of early users to join. As a beta tester, you'll get free access, lifetime perks, and a chance to help shape the product — from an Amazon Ads Verified Partner you can trust.

No credit card required

No credit card required

Free in beta and free extra month free after release

Free in beta and free extra month free after release

25% off for life — limited beta offer

25% off for life — limited beta offer

Access metrics Amazon Ads won’t show you

Access metrics Amazon Ads won’t show you

Be part of shaping the product with your feedback

Be part of shaping the product with your feedback