What Ecommerce Shipping Means Today

Shipping plays a huge role in how well an ecommerce business runs. It affects what customers think of your brand and how much it costs you to get each order out the door. As online competition grows, a shipping process that’s quick, dependable, and easy to manage can give you an edge when you’re trying to win new customers or keep existing ones coming back.

This guide walks through the essentials of ecommerce shipping, including different shipping methods, timelines, carriers, and practical tips you can use as your store grows.

What Ecommerce Shipping Includes

Once a customer places an order, a whole series of steps follow before the package arrives on their doorstep. In most ecommerce businesses, the process looks something like this:

- A customer submits an order.

- You verify inventory.

- Order details are checked for accuracy.

- The product is picked, packed, and made ready for shipment.

- The carrier receives the package and handles the delivery.

If you’re just starting out, you might be packaging orders in your living room and dropping them at your local carrier. But as sales increase – especially if you sell multiple product types, you’ll likely outgrow that setup. At some point, reviewing and improving your shipping workflow becomes essential. If you’re spending more time packing boxes than growing the business, it may be time to bring in extra help or explore outsourcing fulfillment.

Fulfillment vs. Shipping

People often mix these two terms up, so here’s a simple way to think about them:

- Fulfillment includes everything that happens after an order is placed: picking, packing, labeling, and preparing shipments.

- Shipping begins only when the packaged order is officially passed to a carrier.

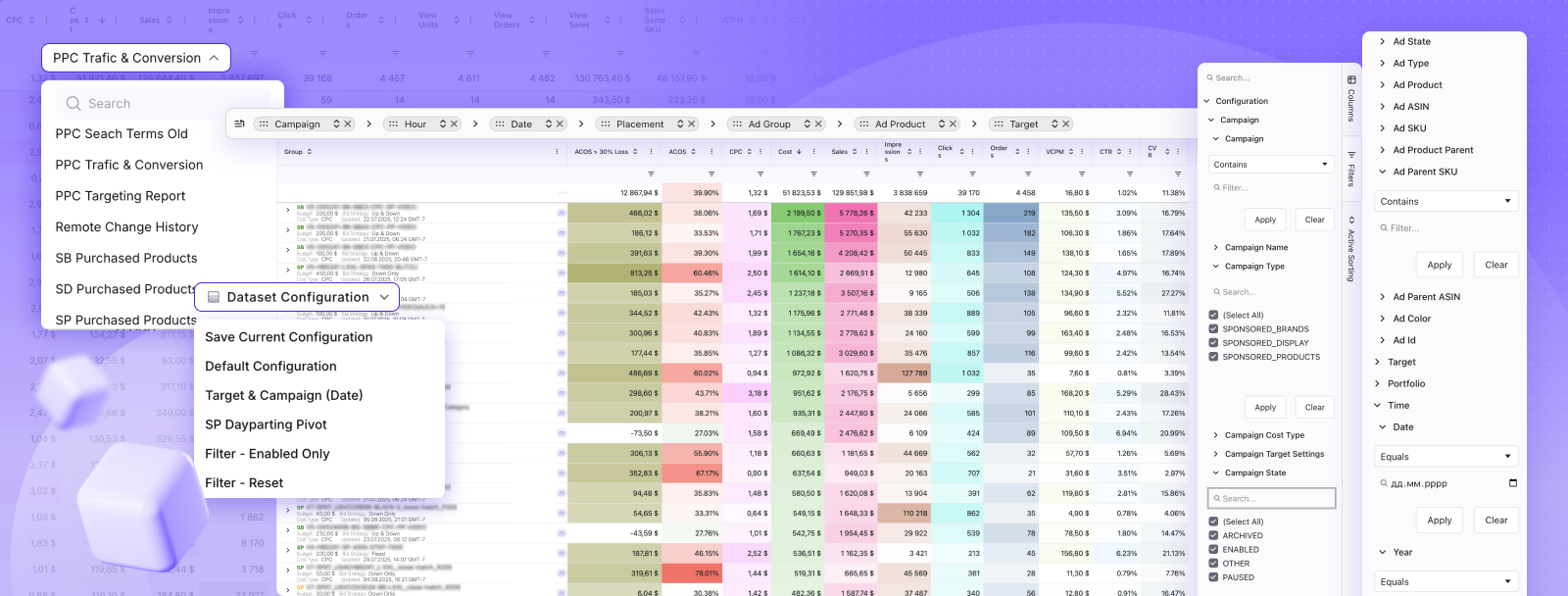

Where WisePPC Fits Into Your Shipping Strategy

At WisePPC, we know that shipping isn’t just an operational step – it’s a major part of how customers experience your brand and how efficiently your business runs. When delivery times slip or costs start rising, it affects everything from conversion rates to repeat purchases. That’s why we built our analytics platform to give you a complete, real-time view of the factors that shape your shipping performance. We pull together your advertising, sales, and operational data so you can see exactly what’s working, where money is being wasted, and how changes in shipping impact your bottom line.

As your business scales, having this level of visibility becomes even more important. With WisePPC, you can track long-term trends, compare performance across marketplaces, and identify issues before they affect customer satisfaction. Whether you manage a small catalog or thousands of SKUs, our tools help you make confident, data-backed decisions that support growth. The result is a smarter, more predictable shipping strategy, and a stronger marketplace presence powered by real insights instead of guesswork.

Understanding Ecommerce Shipping Timelines

Online shoppers expect to know how long delivery will take, and they often choose sellers based on whether the timing matches their needs. Here are some of the most common delivery speeds:

- Standard (3–7 days): The most budget-friendly option. Good for customers who don’t mind waiting a few extra days.

- Two-day delivery: Now considered a baseline expectation for many shoppers who want fast delivery without paying for overnight service.

- Same-day delivery: Useful for items like groceries or essentials. This requires inventory to be held close to the customer or a highly efficient local operation.

- Overnight delivery: Often used for last-minute gifts or urgent purchases. Usually the most expensive option.

- Expedited shipping: Any delivery faster than standard but not necessarily tied to a strict timeline. Depends on the service level offered by your carrier.

Which Shipping Company Works Best for Ecommerce?

There’s no universal “best” carrier – the right choice depends on your budget, product weight and size, destination, and how quickly packages need to arrive. Some commonly used shipping partners include:

- UPS: Covers more than 200 countries and offers options ranging from UPS Ground (1–5 days) to UPS Next Day Air.

- Amazon Shipping: Lets you use Amazon’s transportation network to deliver orders from Amazon or other sales channels. They pick up and deliver seven days a week, with no extra weekend or residential fees.

- FedEx: Known for flexible delivery timelines and strong international coverage across 220+ countries and territories.

- USPS: A cost-effective option for domestic and international shipping, with perks like flat-rate boxes and free package pickup.

Shipping Through Amazon

Amazon offers several delivery options for both shoppers and sellers. Some are exclusive to Prime members, while others apply to all buyers. These include:

- Two-Day Delivery: Fast, free shipping on millions of Prime-eligible items.

- One-Day Delivery: More than 15 million items available in just one day for Prime members.

- Same-Day Delivery: Offered in select areas for eligible items; availability may tighten during peak seasons.

- No-Rush Shipping: Slower delivery in exchange for rewards.

- Subscribe & Save: Automatic recurring deliveries with flexible scheduling and discounts.

- Free Shipping by Amazon: Available when customers meet minimum purchase requirements.

- Domestic Expedited Shipping: Faster delivery for an added fee.

- Standard Delivery: Arrives within 4–5 business days.

Shipping Methods for Ecommerce Businesses

There are several ways to get your products to customers, and each method has benefits depending on your setup:

There’s no single “best” way to ship products – most ecommerce brands end up using a mix of methods as they grow, test new product lines, or expand into new regions. Below are the most common approaches, along with what makes each one helpful (or challenging) depending on your setup.

1. Dropshipping

Dropshipping transfers almost the entire fulfillment workload to a supplier. They store the inventory, pack each order, and ship directly to your customer. It’s appealing for newer sellers because it removes the need for warehousing or upfront bulk inventory purchases.

The trade-off is control, since you don’t physically handle the product, you’re relying on the supplier to pack carefully, ship on time, and maintain quality standards. If they slip up, you’re the one dealing with unhappy customers.

2. Direct-from-Warehouse Shipping

Sometimes called “direct shipping,” this method sends products straight from the supplier or manufacturer to the customer. It’s similar to dropshipping, but usually used when you already have a strong relationship with your supplier or a predictable product lineup.

It can reduce handling time and storage costs, though you’ll still need to coordinate inventory levels and make sure your supplier is prepared to fulfill consistently.

3. Third-Party Shipping (3PL)

A third-party logistics provider manages storage, packing, and shipping for you. It’s a popular choice for ecommerce sellers who want to scale without running a warehouse.

You pay for the service, but you gain professional handling, faster turnaround times, and predictable workflows. The downside is that pricing structures vary, so you’ll want to compare storage, pick-and-pack, and shipping fees before committing.

4. Last-Mile Carriers

In this approach, one carrier (like FedEx or UPS) picks up your package and hands it off to another carrier, often USPS, for the final leg of delivery. It’s a cost-saving strategy for lightweight or low-margin items. The drawback is speed; because more parties are involved, delivery timelines can stretch out, especially in rural areas.

5. Automated Shipping

Automation systems create labels, assign carriers, and in some cases even trigger fulfillment without any manual input. This reduces errors, keeps orders moving during peak seasons, and shrinks the time between receiving an order and getting it out the door.

Automation doesn’t replace carriers, but it simplifies the logistical part of the workflow. It works particularly well for shops with steady order volume or multiple sales channels.

6. Eco-Friendly Shipping

More brands are turning to sustainable shipping options – recycled boxes, biodegradable packing materials, and optimized delivery routes. Customers increasingly appreciate environmentally responsible choices, and in some cases, eco-friendly packaging can even reduce costs by using lighter or more efficient materials. The challenge is balancing sustainability with durability so products still arrive safely.

7. Hybrid Shipping

Most ecommerce businesses end up here. You might handle some orders internally, outsource others to a fulfillment partner, use dropshipping for certain product lines, or rely on different carriers for domestic vs. international shipments. A hybrid approach lets you adapt as your business grows, but it also requires clear tracking and good communication so nothing slips through the cracks.

8. Freight Shipping

Freight is the go-to option for anything oversized or heavy – usually anything over 150 pounds or products with large dimensions.

It’s commonly used by brands shipping bulk inventory to warehouses, or by sellers whose items simply can’t ship through standard parcel carriers. Freight requires more planning, but it often ends up being more cost-effective for large shipments.

Cost-Based Shipping Approaches

You can also organize your shipping options around pricing:

- Flat-rate shipping: One fixed fee, or tiered fixed fees based on weight or price brackets.

- Free shipping: Costs are rolled into product pricing or conditional (“free shipping over $X”).

- Real-time carrier rates: Customers see exact shipping prices based on live data from the carrier.

Why Work With a Fulfillment Provider?

Working with a fulfillment provider can take a significant amount of pressure off your day-to-day operations. Instead of managing inventory, printing labels, and dropping off packages yourself, you send your products to a dedicated warehouse and let their team handle the packing and shipping whenever an order comes in. Providers like Fulfillment by Amazon (FBA) are built to manage these processes at scale, which means they can often move orders faster and more efficiently than an individual seller could on their own.

Because fulfillment providers ship such high volumes, they typically secure better carrier rates, which can bring your shipping costs down. Their established workflows also reduce the likelihood of delays or missed shipments, and many offer multiple warehouse locations so inventory is stored closer to customers. This cuts delivery timelines and makes fast shipping more realistic, even if you’re a smaller brand. Offloading fulfillment also gives you back hours of time to focus on tasks that actually grow your business, like product development, marketing, or improving customer experience.

For businesses planning to expand into new regions, fulfillment partners can make that transition smoother. With products stored across different facilities, you can reach customers in new areas without setting up your own physical infrastructure. The trade-off is cost: storage, handling, and service fees vary by provider, so it’s important to understand how those expenses fit into your overall budget before committing.

Domestic vs. International Shipping

Shipping within your own country is simpler and generally cheaper. International shipping introduces more variables: customs forms, fees, taxes, and regulations.

If you plan to ship internationally, here’s what to keep in mind:

- Identify key countries: Knowing where you expect to ship helps you choose the right carrier.

- Pick a reliable international carrier: Look for tracking, multiple shipping speeds, and strong customer feedback.

- Understand fees: Costs vary widely depending on weight, size, speed, and destination.

- Know the taxes: Duties, VAT, GST – these charges vary by country and can change the total cost significantly.

- Fill out customs paperwork correctly: Missing or inaccurate information can delay or block shipments.

- Follow restrictions: Some countries ban certain items, and ignoring those rules can result in fines.

Shipping Costs to Include in Your Budget

Before you map out your shipping strategy, it helps to understand the different costs that shape the final price of getting an order to a customer. Here’s a simple breakdown:

| Cost Category | What It Covers |

| Carrier fees | Postage, delivery charges, and any rates tied to weight, size, or destination. |

| Packaging materials | Boxes, mailers, tape, protective fillers, and any custom or branded packaging you use. |

| Fulfillment | Labor or service fees for picking, packing, and preparing orders, whether in-house or through a provider. |

| Overhead | Warehouse rent, shipping software, tools, equipment, and other operational expenses. |

| Insurance | Protection against lost, stolen, or damaged packages during transit. |

| Extras | Add-ons like signature confirmation, advanced tracking, or photographic proof of delivery. |

If you’re planning to ship a large number of packages, it’s worth asking carriers about bulk pricing. Many are willing to offer better rates when you commit to consistent volume, which can help reduce overall shipping costs as you scale.

How to Ship Orders in Simple Steps

Once you’re set up to start shipping consistently, the process becomes a routine you can refine over time. Here’s a closer look at each step.

1. Choose the Right Packaging

Good packaging does two jobs: it protects your product and keeps shipping costs reasonable. Too much padding or an oversized box can push the package into a higher price category, but too little protection risks damage. Try out a few combinations of boxes, inserts, and materials to see what holds up best during transit. It’s worth treating this as testing rather than guessing.

2. Add Any Extras

Small touches can go a long way toward building customer loyalty. A thank-you card, a business card, or even a simple note with care instructions helps the order feel more personal. If you offer promotions or discount codes, slipping one into the package can also encourage customers to come back for another purchase.

3. Pack the Order Securely

Once everything is ready to go inside the box, place your items so they can’t shift around. Use enough filler to cushion the product but avoid overpacking. The goal is a tight, tidy fit that keeps the contents stable even if the package gets jostled during shipping. If you’re sending fragile items, consider doing a few “shake tests” to make sure nothing rattles.

4. Print and Attach the Shipping Label

Your shipping label should be clear, easy to scan, and placed on the top panel of the package. Double-check that both the sender and recipient information are correct – small typos can lead to unnecessary delays. If you’re working with a fulfillment provider, they’ll apply labels for you, but it’s still a good idea to understand what the process looks like.

5. Hand Off the Package to Your Carrier

You can drop your package off at a local carrier location or schedule a pickup if your carrier offers that service. Pickup can be a major time-saver once order volume increases. Make sure you keep your tracking number handy; customers almost always want updates, and tracking helps you stay aware of any delays or issues.

6. Notify Your Customer

As soon as the package is on its way, send the tracking information to your customer. Most ecommerce platforms automate these notifications, but even an automated message adds transparency and reduces the chances of support inquiries. Customers appreciate updates – it reassures them that their order is moving and gives them a clearer idea of when it will arrive.

Final Thoughts

Shipping evolves as your business grows. What works when you’re processing a few orders a week may not work when you’re handling dozens or hundreds per day. The key is to stay flexible and adjust your process as you learn what works best for your products, customers, and budget.

Once you’re familiar with the basics, you’ll be able to anticipate your shipping needs, streamline your operations, and create a smoother experience from checkout to delivery. A thoughtful shipping strategy can help you keep customers happy and support steady growth over time.

FAQ

What exactly does ecommerce shipping include?

Ecommerce shipping covers everything involved in getting a product from your business to your customer. That includes packing the order, choosing a carrier, labeling the box, transferring it to the carrier, and making sure it arrives on time. It’s one part of the broader fulfillment process, which also includes picking and preparing orders before they leave the warehouse.

How do I choose the right shipping carrier?

The best carrier for you depends on your product size, delivery speed, destination, and budget. Some businesses prioritize cost, while others need faster delivery or strong international options. Many sellers test a few carriers before settling on the one that consistently delivers the right mix of price and reliability.

Is two-day shipping required to stay competitive?

Not always, but it can make a noticeable difference. Customers increasingly expect fast delivery, especially for everyday products. If two-day shipping isn’t realistic for your business, look for ways to speed up processing times or store inventory closer to customers to shorten transit distances.

What’s the difference between fulfillment and shipping?

Fulfillment includes everything that happens after an order is placed – picking the product, packing it, labeling it, and preparing it for shipment. Shipping is the final handoff to a carrier, who then transports and delivers the package.

Should I offer free shipping to customers?

Free shipping can increase conversions, but it isn’t free for your business. Some sellers build the cost into product pricing, while others offer free shipping only after customers reach a certain order value. The best approach depends on your margins and how sensitive your audience is to shipping fees.

Join the WisePPC Beta and Get Exclusive Access Benefits

WisePPC is now in beta — and we’re inviting a limited number of early users to join. As a beta tester, you'll get free access, lifetime perks, and a chance to help shape the product — from an Amazon Ads Verified Partner you can trust.

No credit card required

No credit card required

Free in beta and free extra month free after release

Free in beta and free extra month free after release

25% off for life — limited beta offer

25% off for life — limited beta offer

Access metrics Amazon Ads won’t show you

Access metrics Amazon Ads won’t show you

Be part of shaping the product with your feedback

Be part of shaping the product with your feedback